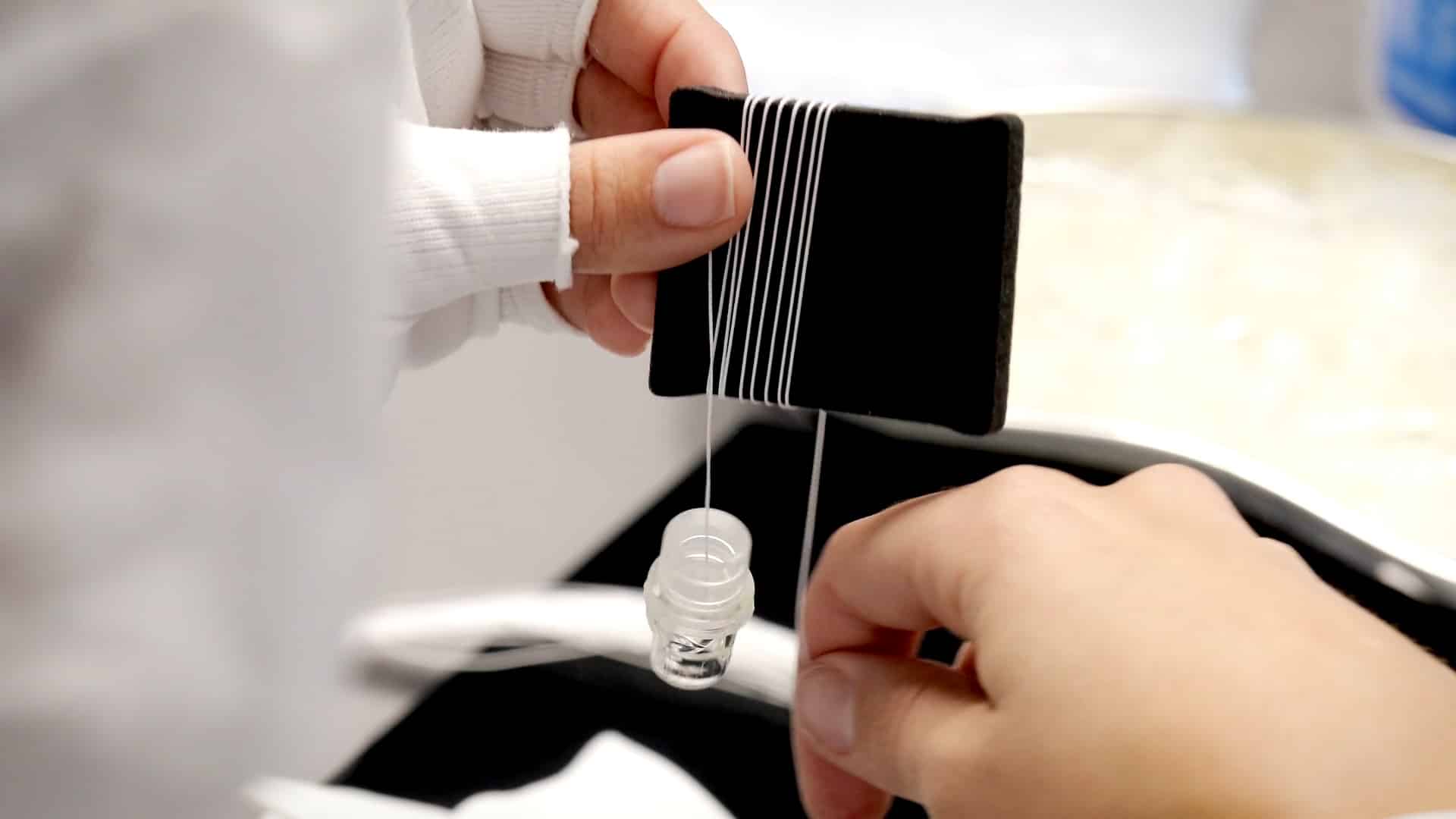

Ovesco relies on in-house production and literally holds the threads in its hands

To ensure continued excellent delivery reliability, Ovesco is increasing its own manufacturing expertise and taking over the production of the thread for the clip products itself

Ovesco Endoscopy AG is a pioneer in the field of innovative products for endoscopic treatments in the gastrointestinal tract. The core products are endoscopic clip systems for the treatment of bleeding and the closure of perforations in the digestive tract. An important component of these products are threads, which are needed to release the clip into the tissue. When it became known that the manufacturer in Switzerland was discontinuing the production of medical threads, Ovesco quickly realised that this important manufacturing process should now be in its own hands in order to continue to guarantee customers the usual delivery reliability.

From the beginning of the cooperation in 2011 until the end of 2022, Ovesco was supplied with threads by the Swiss company Meister & Cie AG. In total, this amounted to more than 300,000 threads, corresponding to a total length of 628 kilometres, which is roughly the distance between Tübingen and the Baltic Sea. As each thread is made up of several strands, around 5,520 kilometres of yarn have been woven so far. This is enough to take you from Tübingen all the way to Mongolia. A thread is braided from several strands of yarn, is about six times thicker than a human hair and can carry an impressive weight of 20 kg.

At the beginning of 2023, the machines were picked up by Ovesco employees themselves in a van and transported to Tübingen. The production staff received intensive training to enable them to produce Ovesco’s high-quality yarns in the future. The entire production process takes place under clean room conditions to ensure the highest quality and cleanliness.

The clip is released in the patient by operating a handwheel in which the thread is clamped. The thread is the link between the user and the clip and is crucial for reliable application and treatment. In-house manufacturing not only makes Ovesco independent of external suppliers, but also provides maximum process control for excellent quality and delivery reliability. Minimising transport distances and packaging waste contributes to product sustainability. Expanding manufacturing expertise is also fully in line with the company’s training concept to empower and develop employees. At the same time, production at the Tübingen site is being continuously expanded, creating secure jobs for the long term.

About Ovesco Endoscopy AG:

Product innovation is one of Ovesco’s core competencies. In this context, cooperation with leading physicians on new product ideas, clinical studies and the introduction of new procedures into medical education is of particular importance to Ovesco.

The team is fully committed to developing products of outstanding quality and exceptional medical value and bringing them to the clinic. The Tübingen-based company’s research strengths have been recognised by national innovation and industry awards. Ovesco has sites in Germany, France, India and the USA.

Contact:

Ovesco Endoscopy AG

Alicia Pulfermuller, Director of Marketing

Friedrich-Miescher-Str. 9, 72076 Tübingen

Tel: +49 (0)7071 / 96528-182

E-Mail: alicia.pulfermuller@ovesco.com

Deutsch

Deutsch  Français

Français